Garment fabric is the material used to make garments. As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the performance effect of color and shape of clothing.

In the big world of clothing, clothing fabrics are varied and changing day by day. But on the whole, high-quality, high-grade fabrics, mostly with comfortable to wear, sweat-absorbing and breathable, draping brace, visual nobility, tactile softness and other aspects of the characteristics. Production of clothing worn in formal social occasions, it is appropriate to choose pure cotton, pure wool, pure silk, pure linen products. With these four pure natural texture fabric production of clothing, most of the higher grade. Sometimes, wearing pure leather production of clothing, is also allowed. We will be the modeling characteristics of different material fabrics and the use of clothing design is briefly described below.

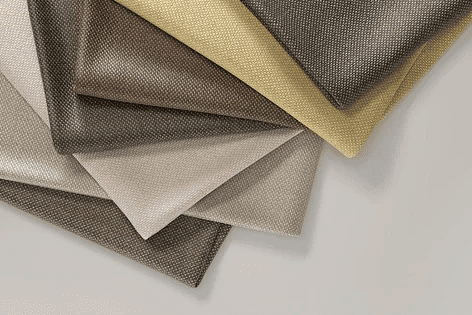

1. Soft fabrics

Soft fabrics are generally lighter and thinner, with good draping, smooth modeling lines and natural spreading of clothing outline. Soft fabrics mainly include knitted fabrics and silk fabrics with sparse fabric structure, as well as soft and thin linen fabrics. Soft knitted fabrics are often used in clothing design linear concise modeling reflecting the body’s beautiful curves; silk, linen and other fabrics are seen in loose and pleated effect of the modeling, the performance of the flow of fabric lines.

2. Contour type fabric

Silhouette fabrics have clear lines with a sense of volume, and can form a full outline of clothing. Commonly there are cotton, polyester-cotton, corduroy, linen and various kinds of thick wool and chemical fiber fabrics, etc. This kind of fabric can be used in the design of highlighting the accuracy of clothing modeling, such as the design of suits and suits.

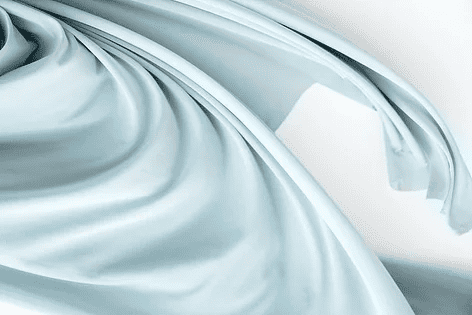

3. Glossy fabrics

Glossy fabrics have smooth surface and can reflect bright light, with a sense of glittering. This kind of fabric includes satin structured fabric. It is most often used in night dresses or stage performance clothes to produce a gorgeous and dazzling strong visual effect. Glossy fabric in the performance of the dress modeling freedom is very wide, can have simple design or more exaggerated modeling way.

4. Heavy fabric

Thick and heavy fabrics are thick and scraping, which can produce stable modeling effect, including all kinds of thick tweed and quilting fabrics. Its fabric has a sense of shape expansion, should not use too much pleating and stacking, the design of A-type and H-type modeling is most appropriate.

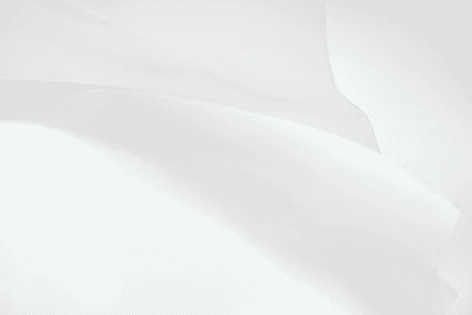

5. Transparent fabric

Transparent fabric is light and transparent, with elegant and mysterious art effect. Including cotton, silk, chemical fiber fabrics, such as georgette, satin silk, chemical fiber lace, etc.. In order to express the transparency of the fabric, it is often used in the natural and full lines, rich in change of H-type and round platform type design shape.

Properties of clothing fabrics

The following is a brief introduction to the characteristics of common garment fabrics

1. Cotton fabric

Cotton is a general term for all types of cotton textiles. It is mostly used to make fashion, casual wear, underwear and shirts. Its advantages are that it is easy to keep warm, soft to the body, and has excellent moisture absorption and breathability. Its disadvantage is that it is easy to shrink, easy to wrinkle, the appearance is not very straight and beautiful, and must be ironed from time to time when wearing.

2. Linen

Linen is a fabric made of linen, ramie, jute, sisal, banana hemp and other kinds of hemp plant fibers. It is generally used to make casual wear and work wear, and is also used to make ordinary summer clothes. Its advantage is that it is very strong, moisture absorption, thermal conductivity, breathability is very good. Its disadvantage is that it is not very comfortable to wear, the appearance is more rough, raw.

3. Silk

Silk is a variety of silk fabrics woven from silk as a raw material, the collective name. As with cotton, it has many varieties and different personalities. It can be used to make a variety of clothing, especially suitable for the production of women’s clothing. Its strengths are light, fit, soft, smooth, breathable, colorful, lustrous, noble and elegant, comfortable to wear. Its shortcomings are easy to crease, easy to absorb the body, not strong enough, fading faster.

4. Tweed

Tweed is also called wool, it is a general term for fabrics woven from various types of wool and cashmere. It is usually used to make dresses, suits, coats and other formal, high-grade clothing. Its advantages are wrinkle and wear resistance, soft hand, elegant and brace, elasticity and warmth. Its disadvantage is mainly washing is more difficult, not very suitable for making summer clothes.

5. Leather

Leather is tanned animal fur fabric. It is mostly used to make fashion, winter clothing. And can be divided into two categories: one is leather, that is, after the fur treatment of leather. The second is fur, that is, processed leather with fur. Its advantage is light and warm, elegant and luxurious. Its disadvantage is that it is expensive, storage, care requirements are high, so it is not popular.

6. Chemical fiber

Chemical fiber is short for chemical fiber. It is the use of polymer compounds as raw materials for the production of fibers of textiles. It is usually divided into two categories of artificial fibers and synthetic fibers. They share the advantages of bright colors, soft texture, drape, smooth and comfortable. Their disadvantages are wear resistance, heat resistance, moisture absorption, breathability is poor, easy to deformation in the heat, easy to generate static electricity. Although it can be used to make various types of clothing, but the overall grade is not high, it is difficult to get into the hall of fame.

7. Mixed spinning

Blending is the natural fibers and chemical fibers in accordance with a certain ratio, mixed textile fabrics, can be used to make a variety of clothing. Its strengths, is both the absorption of cotton, hemp, silk, wool and chemical fiber each of the advantages, but also as far as possible to avoid their respective shortcomings, and relatively low in value, so popular.

8. Cotton

Cotton fabric is cotton as raw material, through the loom, by the warp and weft yarn vertical and horizontal sinking interwoven textiles. At present, in accordance with the actual processing of cotton sources and distinguished as virgin cotton fabrics and recycled cotton fabrics.

Pure cotton fabric is divided into:

- Native white fabric: ordinary cloth surface, fine cloth, coarse cloth, canvas, twill blank cloth, primary color cloth.

- Color cloth: vulcanized blue cloth, vulcanized ink cloth, shilling blue cloth, shilling gray cloth, color poplin, various colors of khaki, various colors of tweed.

- Flower cloth: is printed and dyed on a variety of colors and patterns of cloth. Such as: plain printing cloth, printing twill cloth, printing beige, printing straight tribute.

- Color woven cloth: It is the yarn or thread first dyed, and then woven on the machine into cloth such as striped cloth, sheet cloth, velvet, thread tweed, decorative cloth, etc.

The characteristics of pure cotton woven fabrics:

- Moisture absorption: cotton fiber has good moisture absorption, in normal conditions, the fiber can absorb moisture from the surrounding atmosphere, its moisture content of 8-10%, so it touches human skin, so that people feel soft and not stiff. If the cotton humidity increases, the surrounding temperature is higher, the amount of water contained in the fiber will all evaporate and dissipate, so that the fabric maintains a state of water balance, so that people feel comfortable.

- Moisture retention: Because cotton fiber is a poor conductor of heat and electricity, heat transfer coefficient is very low, and because cotton fiber itself has porous, high elasticity advantages, between the fibers can accumulate a lot of air, air and is a poor conductor of heat and electricity, so, cotton fiber textiles have good moisture retention, wearing cotton woven clothing so that people feel warm.

- Heat resistance: cotton fabrics heat resistance is good, below 110 degrees Celsius, will only cause the evaporation of water on the fabric, will not damage the fiber, so cotton fabrics at room temperature, wearing use, washing printing and dyeing, etc. on the fabric are not affected, which improves the cotton fabrics washable and wearable taking performance.

- Alkali resistance: cotton fiber resistance to alkali, cotton fiber in alkali solution, fiber destruction does not occur, the performance is conducive to taking after the pollution of the washing, disinfection in addition to impurities, but also on cotton textiles for dyeing, printing and a variety of technological processes to produce more cotton weaving new varieties.

- Health: cotton fiber is a natural fiber, its main component is cellulose, there are a small amount of wax-like substances and nitrogenous substances and pectin. Cotton fabric by a number of checks and practice, woven fabrics and skin contact without any stimulation, no negative effects, long wear on the human body is beneficial and harmless, good health performance.

Disadvantages of pure cotton woven fabrics:

- Easy to wrinkle, and wrinkled more difficult to smooth out.

- Easy to shrink, cotton clothing shrinkage rate is 2% to 5%, after special processing, or washing treatment exception.

- easy to deformation, cotton clothing will be easy to deformation, especially summer clothes, because the fabric is relatively thin.

9. Lycra fabric

Lycra is just a trade name for INVISTA (acquired by Koch Industries for $4.4 billion in 2004), a former wholly owned subsidiary of DuPont, which has become synonymous with all spandex yarns due to the company’s exclusive market position in the spandex sector. It has completely replaced the traditional elastic rubber yarn, and Lycra is an almost essential component in gymnastic wear and swimwear, garments with special requirements. It allows you to reveal your curves and stretch your gel body without feeling compressed. Lycra is not only versatile in everyday clothing, it is also a pet in the kaleidoscope of fashion designers who create fashions. Lycra has thus been called a magical fiber by delighted people and given the name “Sphinx” of the Egyptian sphinx, which adds to its mystique.

Many of our designer friends like to say that they have used a little Lycra when talking about their recent work. Perhaps it’s not just that the garments with Lycra are quite fashionable, but the word itself has a strong fashionable connotation.

Lycra is a new type of fiber introduced by DuPont in the U.S. At present, as long as the garments with Lycra are hung with a triangular hangtag, this hangtag has also become a symbol of high quality. So, where exactly is the advantage of Lycra? According to the quality statement introduced by DuPont, Lycra is different from traditional elastic fibers in that it can stretch up to 500% and can return to its original shape. That is to say, this fiber can be stretched very easily, after the reply but can be tightly attached to the surface of the body, the binding force on the body is very small. Lycra can be used with any fabric, including wool, linen, silk and cotton, to increase the fit, elasticity and looseness of the fabric’s natural characteristics, and feel more flexible when moving. And Lycra, unlike most spandex, has a special chemical structure that does not grow mold even when wet and sealed in a hot and humid space.

Therefore, Lycra is called a “friendly” fiber, not only because it can be thoroughly integrated with natural and man-made fibers, but also to increase the comfort, corseting, freedom of movement and longevity of the fabric or garment.

Lycra (LYCRA) can be freely stretched 4 to 7 times and quickly return to its original length after external forces are released. It cannot be used alone and can be interwoven with any other man-made or natural fiber. It does not change the appearance of the fabric, it is an invisible fiber that can greatly improve the performance of the fabric. Lycra has outstanding stretchability. For knits, its multi-directional stretch is determined by the fabric itself, and Lycra brings only the elasticity of stretching and returning. Woven fabrics are only stretchable in the direction in which the Lycra is woven, such as warp knit (straight line) or weft knit (cross line). While pants benefit from warp direction stretch, woven fabrics with bi-directional stretch containing Lycra provide great comfort and freedom of movement in both directions. Therefore, when Lycra is added to women’s garments such as pants and jackets, the folds can easily return automatically, and the clothes are more comfortable and less deformable, so that they can move freely and feel free and new. Even if the production of strict suits, jackets, etc., there is no sense of urgency and constraint, sweatshirts, underwear, bodybuilding pants and other knitted products to add a little Lycra, both fit and comfortable, wearing the body stretch freely, can move with.

Lycra is extremely versatile and adds extra comfort to all types of garments, including underwear, tailored jackets, suits, dresses, pants, knitwear and more. It greatly improves the feel, drape and crease recovery of fabrics, enhances the comfort and fit of various garments, and gives new vitality to various garments, especially the Lycra-wool blends developed by DuPont and the International Wool Bureau. It provides a new concept for the textile industry in the late 20th and 21st centuries.

10. Blending

Blended chemical fiber fabrics are chemical fibers and other cotton, wool, silk, hemp and other natural fibers mixed spinning woven into the textile products. For example: polyester-cotton cloth, polyester-wool wada tweed, etc.

For example, polyester-cotton blend is the main component of polyester, using 65%-67% polyester and 33%-35% cotton mixed yarn woven into the textile, polyester-cotton cloth is commonly known as cotton does cool. Features: both highlight the style of polyester and the strengths of cotton fabric, elasticity and wear resistance in dry and wet conditions are better, size stability, shrinkage is small, with a straight, not easy to wrinkle, easy to wash, fast dry characteristics, can not be ironed with high temperature and boiling water immersion.

11. Oxford Spinning

A shirt fabric with a soft feel and a plain variegated or squared tissue structure.

In the 1900s, in order to fight against the flashy and extravagant clothing trend at that time, a small group of maverick students at Oxford University designed and processed by themselves using combed cotton fabric, which had a two-color effect, with a harmonious and quiet color, good breathability, comfort and naturalness. Thus promoted, the fabric became the special use of Oxford University uniforms, and then popular in Europe and the United States for a hundred years, the world called Oxford spinning.

Oxford cloth is also called Oxford spinning, mostly using polyester polyester-cotton blended yarn and cotton yarn interweaving, using the weft heavy flat or square flat organization. With easy to wash and dry, feel soft, good moisture absorption, comfortable to wear and other characteristics. The appearance is like color woven fabric.

Because the earliest Oxford University student uniform shirts using this cotton fabric and named.

Attachment: the main varieties of Oxford cloth

- Oxford cloth, specially used for making all kinds of bags.

- Nylon Oxford cloth, mainly for the production of flood and rain supplies.

- Full elastic Oxford cloth, mainly for making bags.

- Oxford cloth with lattice, mainly for making all kinds of bags.

- Weft Oxford cloth, mainly making all kinds of bags.

Oxford spinning is a kind of fabric weaving method, refers to the weaving of the horizontal and vertical cotton yarn overlapping order, Oxford spinning fabric actually belongs to the shirt fabric in the low grade.

At present, Oxford spinning fabric has pure cotton, polyester and cotton blend.

12. linen

Linen is a fabric made of various hemp plant fibers such as flax, ramie, jute, sisal, and plantain. It is generally used to make casual clothes and work clothes, and nowadays it is also used to make ordinary summer clothes. Its advantage is that it is very strong, moisture absorption, thermal conductivity, breathability is very good. Its disadvantage is that it is not very comfortable to wear, the appearance is more rough, raw.

13. Knitted fabric

Knitted fabric, also known as sweat cloth, refers to the production of underwear weft flat knitted fabric. Square meter dry weight is generally 80-120g/cm, smooth, clear pattern, fine texture, smooth feel, longitudinal and transverse with good extensibility, and transverse than longitudinal extensibility. Moisture absorption and breathability is good, but there is dispersion and rolled edges, and sometimes there is a skewed coil phenomenon. The common sweat cloths are bleached sweat cloth, special white sweat cloth, fine bleached sweat cloth, burnt wool mercerized sweat cloth; according to the different dyeing and finishing process, there are plain sweat cloth, printed sweat cloth, navy strip sweat cloth; according to the different raw materials used, there are blended sweat cloth, silk sweat cloth, acrylic sweat cloth, polyester sweat cloth, ramie sweat cloth, etc.

14. Polyester

Polyester is an important variety of synthetic fiber, is the trade name of our polyester fiber. It is made of purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (EG) as raw material by esterification or ester exchange and polycondensation reaction into a fiber polymer – polyethylene terephthalate (PET), by spinning and post-treatment made of fiber.

Identification of the composition of clothing fabrics

A simple way to identify the composition of clothing fabrics is the combustion method. The practice is to draw a strand of cloth yarn containing warp and weft yarn at the sewing edge of the garment, ignite it with fire, observe the state of the burning flame, smell the odor issued by the burning cloth yarn, see the residue of the burning, so as to determine whether the fabric composition marked on the durability label of the garment matches, in order to identify the authenticity of the fabric composition.

1. Cotton fiber and linen fiber

Cotton fiber and hemp fiber are just near the flame that is burning, burning rapidly, the flame is yellow, blue smoke. The difference between the two in the smell of burning and burning ashes is that cotton burning paper odor, hemp burning issued the smell of grass ash; after burning, cotton has very little powder ashes, black or gray, hemp is a small amount of gray powder ashes.

2. Wool fiber and silk

Wool smoldering in fire, burning blistering, slow burning speed, emitting burning hair burnt odor, after burning ashes more lustrous black spherical particles, a finger pressure that is broken. Silk fire shrinkage into a doughnut, slow burning speed, accompanied by sizzling sound, emitting hair burning smell, burned into small black-brown spherical ashes, hand twisting that broken.

3. Wool fiber and silk

Wool smoldering in fire, burning blistering, slow burning speed, emitting burning hair burnt odor, after burning ashes more lustrous black spherical particles, a finger pressure that is broken. Silk fire shrinkage into a doughnut, slow burning speed, accompanied by sizzling sound, emitting hair burning smell, burned into small black-brown spherical ashes, hand twisting that broken.

4. Nylon and polyester

Nylon-synonymous polyamide fiber, near the flame that is quickly curled and melted into a white gel, molten in the flame dripping and blistering, burning without flame, leaving the flame is difficult to continue to burn, emitting the smell of celery, light brown molten material after cooling is not easy to shred. Polyester scientific name polyester fiber, easy to ignite, near the flame that melting shrinkage, burning while melting black smoke, a yellow flame, emitting aromatic odor, after burning ashes for the hard black-brown block, with fingers can be twisted.

5. Acrylic and polypropylene

Acryl, also known as polyacrylonitrile fiber, near the fire softening and melting, black smoke on fire, white flame, rapid combustion from the flame, emitting a pungent smell of burning flesh, the ashes after burning for irregular black hard, easy to twist and break. Polypropylene fiber scientific name, near the flame that melt shrinkage, flammable, slow burning and black smoke from the fire, the upper end of the flame yellow, the lower end of blue, emitting petroleum odor, after burning ashes for hard round light yellow-brown particles, hand twist fragile.

6. Vinylon and chlorine spandex

Vinylon scientific name polyvinyl alcohol formaldehyde fiber, not easy to ignite, near the flame melt shrinkage, burning a little flame at the top, to be fiber are melted into a gel flame becomes large, there is thick black smoke, emitting a bitter smell, after burning the remaining small black bead-like particles, available finger crushing. Chlorine spandex, the scientific name of polyvinyl chloride fiber, difficult to burn, away from the fire that is extinguished, the flame is yellow, the lower end of the green white smoke, emitting irritating pungent pungent acidic smell, burning ashes for the black-brown irregular hard block, fingers are not easy to twist.

7. Spandex and fluorine spandex

Spandex is known as polyurethane fiber, near the fire side of the molten side combustion, burning flame is blue, leaving the fire continues to melt combustion, emitting a special irritating odor, burning ashes for soft fluffy black ash. Fluorine spandex scientific name of polytetrafluoroethylene fiber, ISO organization called it fluorite fiber, near the flame only melting, difficult to ignite, not burning, the edge of the flame is blue-green carbonization, melting and decomposition, gas toxic, melted material for hard round black beads. Fluorine fiber in the textile industry is often used in the manufacture of high-performance sewing thread.

8. Viscose fiber and copper ammonium fiber

Viscose fiber is flammable, burning quickly, the flame is yellow, emitting the smell of burning paper, after burning ash less, a smooth twisted band of light gray or gray-white fine powder. Copper ammonium fiber commonly known as tiger cotton, near the flame that is burning, burning fast, the flame is yellow, emitting ester acid smell, after burning ashes very little, only a small amount of gray and black ash.

Identification of pure wool fabrics

Pure wool fabric has natural and soft color, good warmth, and is the fabric of choice for making high-grade suits and coats. But now there are more and more imitation wool fabrics, with the improvement of textile technology, it has reached a level that most customers can hardly identify, but the color, warmth, feel, etc. are still far from pure wool fabrics. Here are a few ways to identify pure wool fabrics for your reference when selecting clothing and fabrics.

1. Hand touch feeling

Pure wool fabrics usually feel soft and smooth, long wool fabrics feel soft and smooth with the hair, against the hair has a tingling feeling. And blended or pure chemical fiber products, some less than soft, some too soft and loose, and a sticky feeling.

2. Look at the color and luster

Pure wool fabric color natural soft, bright and no old feeling. In contrast, blended or pure chemical fiber fabrics, or luster is darker, or a sense of flash.

3. Elasticity

Use your hand to defend the thing tightly, and then immediately release, see the fabric elasticity. Pure wool fabric rebound rate is high, can quickly restore the original state, and blended or chemical fiber products, the wrinkle resistance is poor, most of the more obvious pleat marks, or slow recovery.

4. Burning method identification

Take a bunch of yarn, burn with fire, pure wool fiber smell like burning hair, chemical fiber fabric smell like burning plastic. The harder the particles after burning, the more chemical fiber components.

5. Single identification

All animal hair is scaly under the microscope, if it is a long hair fabric, just take a hair like the picture above rub a few times will move up or down (in order to master this skill can first take a hair to do the test), if it is ordinary fabric, take a yarn, cut 2 cm of the two sections into one by one fiber in the hand rub four or five times, see if they will move.

Woolen fabric raw materials

At present, the animal wool fiber used in the wool fabric in the market, there are several kinds of sheep wool, goat wool, camel wool and rabbit hair.

1. Sheep’s wool

People’s daily use of the largest amount of sweaters, wool, felt, etc. is mainly sheep body dense with sheep’s wool. In the knitting industry, sheep’s wool is the most used, so “wool” has become the abbreviation of sheep’s wool.

The world’s largest producers of sheep’s wool are Australia, the Commonwealth of Independent States, New Zealand, Argentina, and China. The higher the count, the better the quality, and the higher the grade, the worse the quality.

Australian wool, which has always been admired, belongs to the Merino breed of sheep and is produced in Australia, hence the name. Its wool fiber is fine and long, and it is the best quality of sheep wool. Other breeds such as New Zealand, South America, European countries, the Southern Alps, etc. have been bred and are well known around the world.

Shetland wool is also a common breed. Shetland wool, formerly known as Shetland wool, is named after the Shetland Islands in Scotland, England. Because the Shetland wool is mainly pile wool and mixed with more coarse and bumpy wool, this natural mixture of coarse and fine, forming a rich and fluffy, soft and not delicate, luster and elasticity of the characteristics of the Shetland wool fabric, with a rough style. However, due to the low production of Sherpa wool, the demand exceeds the supply, and the so-called “Sherpa wool sweater” sold in the market is mostly made of semi-fine wool from New Zealand. Some are called “Sherwood” sweaters, selling for less than a hundred yuan each or even just a few dozen yuan, in fact, they are imitation Sherwood style products, some “Sherwood” is spun from a variety of miscellaneous wool, can only do coarse wool, the price is also cheaper.

There are also inexpensive, popular with consumers of sheep’s wool, in fact, lamb’s wool, its feel coarse, more made into wool yarn use.

2. Goat wool

Goat hair refers to the coarse and dead wool cut from goat hair. Generally, the fine hairs on goat hair are too short to be spun, and the coarse hairs can only be used to make brushes and brushes, with the exception of mohair. Mohair is Angora goat hair, produced in Turkey’s Angola province, North America and South Asia, is a high-quality wool fiber, smooth surface, very little curl, long and coarse, with silk-like soft and strong luster, excellent resilience, wear resistance and high strength, is the ideal raw material for weaving jacquard blankets, long wool pile, smooth wool coat tweed, artificial fur and other advanced fabrics. Coarse stick needle hand-knitted mohair shirts, draped with soft silk-like fog-like fibers, constitute a noble, lively and rugged style of clothing, and are loved by people. Zhongwei Mountain Wool in the northwest of China also belongs to the mohair category. However, in the market, some people call the fluffy style of acrylic puff yarn “mohair” for sale, causing misunderstanding, that acrylic puff yarn, at best, can only be called “imitation mohair”.

3. Alpaca wool

Alpaca wool (ALPACA), also known as “camel wool”, fiber length of 20-40 cm, and white, brown, gray, black and other colors, because 90% of production in Peru, also known as “Peruvian wool”. It has two varieties, one with curly fibers and silvery luster, and the other with straight fibers and less curl, with a luster similar to mohair, often blended with other fibers as a high quality material for making high-end clothing. At present, most of the camel wool in the market is from Eastern Europe.

4. Rabbit wool

Rabbit wool is loved by people for its light, fine, soft, warm and cheap characteristics. It is composed of fine and soft fleece and coarse wool, mainly ordinary domestic rabbit and Angora rabbit hair, and the latter is of superior quality. The difference between rabbit hair and wool is that the fibers are long and thin, and the surface is especially smooth and easy to identify. Because of its low strength, rabbit hair is not easy to be spun alone, so it is mostly blended with wool or other fibers to make knitted products and clothing fabrics such as ladies’ tweed and coat tweed.